MicroMag Filters

Magnetic Filtration the Micromag Way

Micromag is used to remove ferrous or para-magnetic contamination from fluids. The unit is especially effective with machine tool oils and coolants.

Re-circulating magnetic particles in any machine tool especially precision grinding applications has many negative effects:

- Pump, slide way and hydraulic seals wear prematurely

- Oil and coolant life is massively reduced by bacterial growth, which can be associated with foreign bodies such as metallic particles. In some cases this stops the fluids from performing their critical tasks of cooling and lubricating at the cutting face.

- Surface finish and component accuracy can also be affected. Cutting wheels need to be to redressed more often, resulting in higher operating costs and reduced profit.

Many state of the art machine tools are still being supplied with sub-standard cheap-fix filtration systems which sometimes are no better than expensive strainers.

Micromag's high magnetic forces can attract even sub-micron sized particles, ensuring that even the dirtiest of fluids are thoroughly treated prior to use.

Micromag is available in three housing sizes 5" & 10" with 1" inlet / outlet ports and a 20" unit with 1" ports. All units are supplied with port adaptors to suit most pipe connection sizes.

| Kleenoil USA Part # | MM5 | MM10 | MM20 |

| Photo |  |

|

|

| Weight | 5.51 lbs | 11.02 lbs | 18.74 lbs |

| 2.5 kg | 5 kg | 8.5 kg | |

| Height | 7.36 inches | 12.36 inches | 23.78 inches |

| 187 mm | 314 mm | 604 mm | |

| Diameter | 3.54 inches | 3.54 inches | 3.15 inches |

| 90 mm | 90 mm | 80 mm | |

| Magnet Material | Rare Earth | Rare Earth | Rare Earth |

|

|

Magnetic Filtration The system Incorporates the most powerful, natural Rare Earth Magnetic material to produce extreme magnetic flux fields removing metal debris from the oil. With the convenient mount on the Kleenoil Unit the Micromag is easily viewed, whereby oil from the source is clearly seen passing through the pump into the magnetic core where ALL metal debris is visibly removed, then through into the Kleenoil Units where it continues to be ‘polished’. The Magnetic Process Contaminated fluid enters the inlet to be equally dispersed via radial channels, thus slowing the fluid down to pass outside the centrally mounted ‘rare earth’ magnetic core, where you will see the particle capture, as more particles attract to the core the magnetic flux circuit geometry generates a controlled build up of contamination, so ensuring that the filter will not block - the filtered fluid then flows through return slots through the centre exiting via the outlet into the Kleenoil System. The Filtration Process The oil has been cleansed of all magnetic particulate, to be passed through the Kleenoil System, either in single, twin or four unit form, whereby all remaining contaminates are removed through cellulose media down to 1 micron relative as well as all water. ( pump & motors are available 240v / 110v in any configuration of sizes to suit the application. |

|

|

|

Cleaning the Core Using the supplied cleaning tool, a fully contaminated core can be cleaned in under 30 seconds! leaving you with only metallic particles, which can be easily disposed of, no dirty cartridges! |

| Contamined Core | Cleaning Core | Clean Core |

| Segments for Micromag: | Applications that Benefit from Micromag: | |

|

|

|

How it Works

|

|

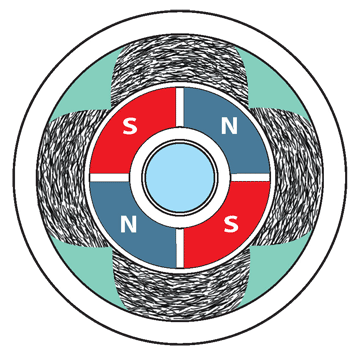

The patent-pending Micromag comprises: hard-wearing clear filter body, anodised aluminium lid,high intensity magnetic core. The magnetic core incorporates neodymium iron boron magnetic material that generates extremely high-intensity magnetic fields.

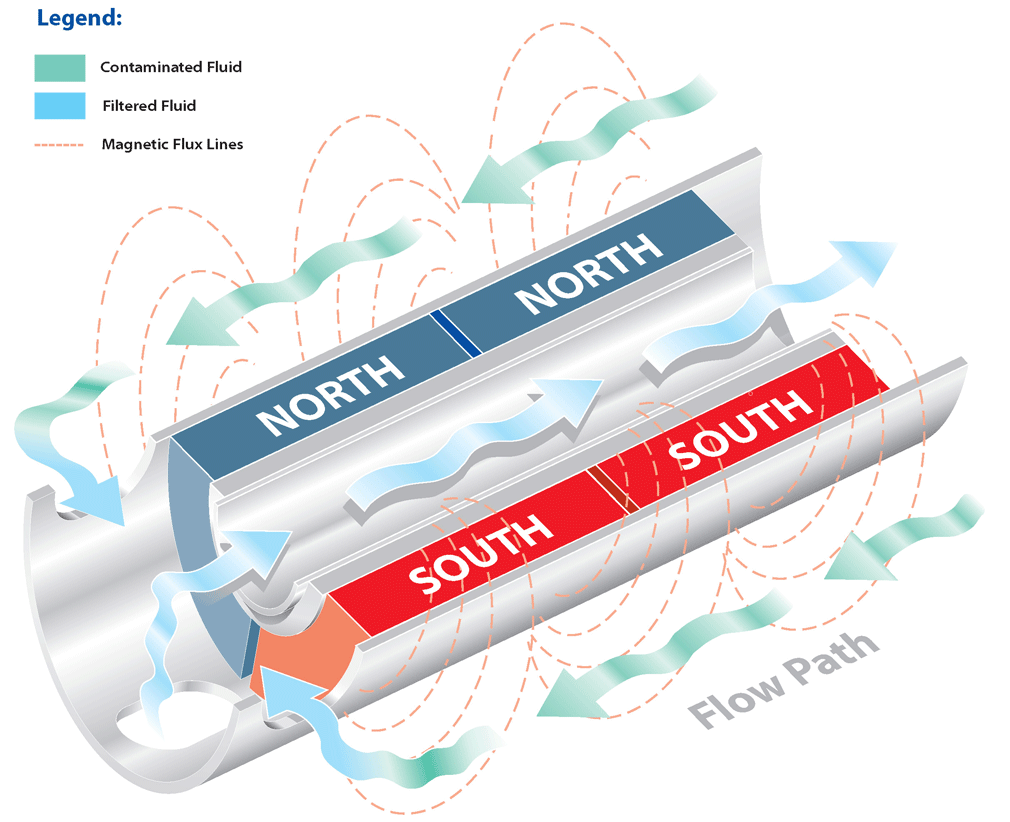

Fluid enters the housing via the inlet port and is evenly distributed around the underside of the aluminium lid via radial tapered flow channels. The fluid to pass down the outside of the magnetic core where magnetic particles are attracted by the high intensity magnetic field. The fluid then passes through four return slots at the bottom of the core, up through the central return tube and out of the outlet port.

The centrally positioned magnetic core utilises a patent-pending geometric magnetic circuit. Magnets are arranged around a central magnetic flux return shield to ensure that all of the magnets' performance is used whilst still allowing unaffected fluid flow even when the core is fully saturated with contamination.

The 10" bodied Micromag core can hold 2kgs of contamination before the unit requires cleaning. This allows for extended operating time and minimises downtime. Where contamination generation is high the 20",which is capable of holding 4.5kgs, Micromag should be used. Where loading is extreme and machine operation is critical Micromags can be installed on a duplex set up.

The clear filter housing gives the operator a visual indication of when the unit requires cleaning. Cleaning is very simple and is done using the supplied cleaning tool. The units can be fully cleaned and back on line within one minute.

Benefits Over Conventional Filtration

- Sub-micron filtration efficiency: if the particle is magnetic Micromag will remove it

- No loss of fluid - no oil sodden cartridges to dispose of

- No pressure drop even when fully loaded with contamination

- No consumables required, ever! Once purchased the unit does not require ongoing spending. Operating costs are minimal

- No maintenance required - only operator intervention to clean

- Reduced environmental impact: all you are left with is metallic material which can be collected by your material supplier

- Capable of removing abrasives and non-magnetic material by means of heterocoagulation

- Reduce machine downtime, increased productivity

- Visual inspection of fluid being filtered

Kleenoil USA Offers Custom Filter Carts with Both Kleenoil Onboard Oil Recycling Systems and Micromag for the Ultimate in Filtration